Optimizing Manufacturing Efficiency with BMP

How Business Management Platforms Solve Manufacturing Challenges: Insights on Streamlined Processes and Sustainable Solutions

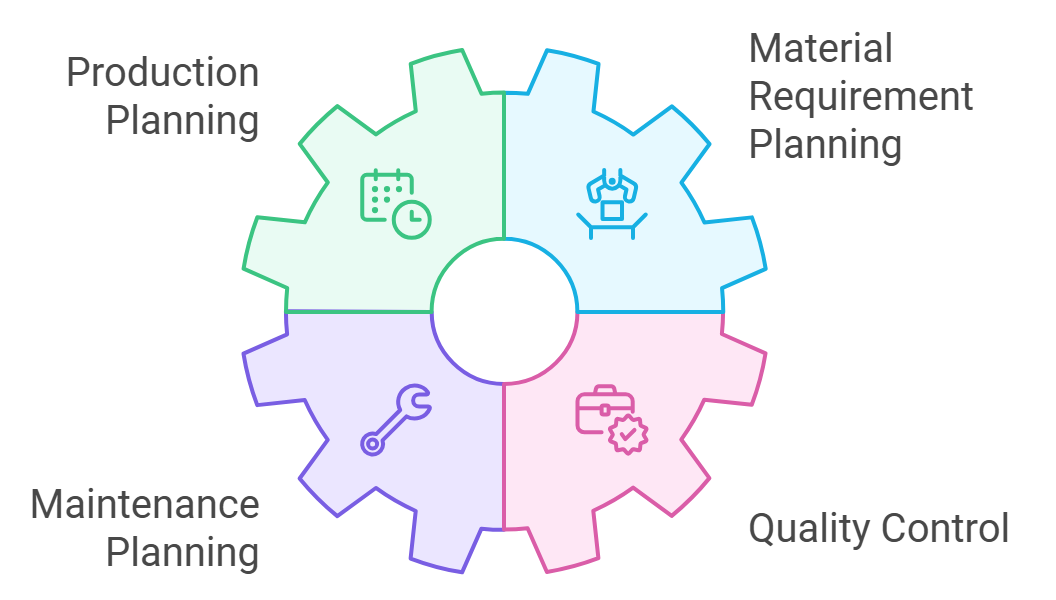

In the manufacturing industry, seamless operations and high-quality control are critical to maintaining a competitive edge. Yet, many manufacturers face persistent issues, from production planning inefficiencies to supply chain disruptions. Integrating Enterprise Resource Planning (ERP) and Business Management Platforms (BMP) into key areas like production, material management, and maintenance can address these challenges effectively. Here’s an analysis of the major challenges in manufacturing BMP systems that offer solutions.

Production Planning and Downtime Reduction

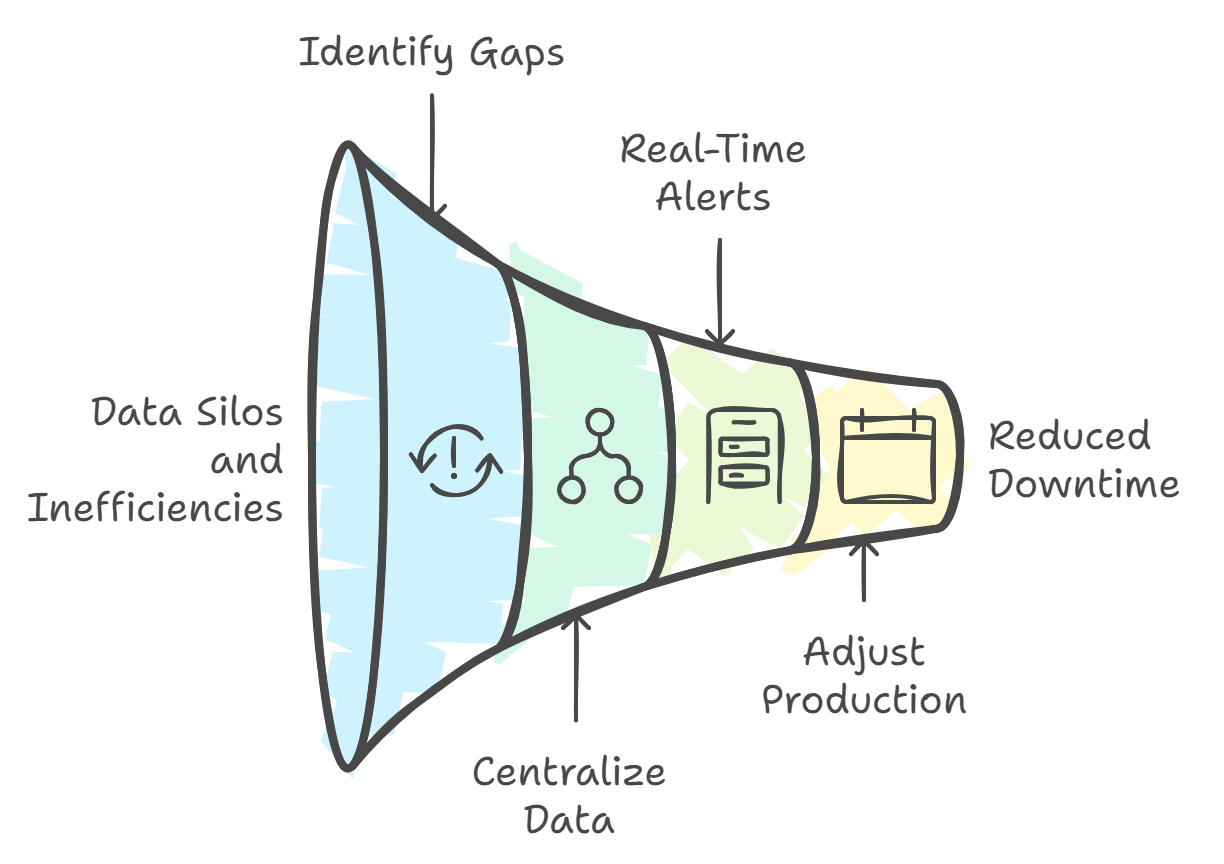

Production planning in manufacturing often suffers from inefficiencies due to data silos and limited real-time tracking, leading to unexpected production halts. According to Forbes, unplanned downtime can cost manufacturers significant amounts, with estimates indicating losses up to $50 billion per year across industries. These stoppages are primarily due to gaps in synchronization between production schedules and inventory levels, causing operational delays.

Imagine an automotive parts manufacturer facing frequent production halts due to a lack of coordination between production scheduling and inventory availability. Without synchronized data, managers often realize too late that critical materials are out of stock, causing machinery downtime and leading to costly rescheduling.

BMP systems address these gaps by centralizing data from all departments, including production and inventory, in real-time. This integration ensures that production managers are alerted to material shortages and supply chain delays, allowing them to make adjustments and reduce downtime. Additionally, automated scheduling within ERP frameworks helps manufacturers better align production with supply chain activities.

Material Requirement Planning (MRP) and Supply Chain Management

The globalized nature of supply chains creates complexities in material management, especially during disruptions. According to Deloitte, manufacturers that heavily rely on overseas suppliers faced severe challenges during the COVID-19 pandemic, highlighting the need for adaptable, resilient MRP systems. For instance, consider an electronics manufacturer that relies on specific semiconductor components from overseas suppliers. Due to international shipping delays, they frequently encounter inventory shortages, disrupting the production line and delaying order fulfillment.

Modern BMP systems with MRP modules use AI-driven forecasting tools that provide visibility across the entire supply chain, allowing manufacturers to anticipate material requirements based on real-time demand. This approach reduces waste and inventory holding costs while enabling manufacturers to avoid stockouts by responding to shifting supply conditions quickly.

Maintenance Planning for Equipment Optimization

Efficient maintenance planning is critical for maximizing uptime and reducing unexpected breakdowns, yet many manufacturers lack systems for monitoring equipment health proactively. According to the European Commission, predictive maintenance could be a game-changer for European competitiveness by enhancing operational efficiency and reducing reactive maintenance costs.

BMP systems incorporate predictive maintenance capabilities that monitor equipment performance in real-time, using sensors to track wear and usage patterns. This data-driven approach enables manufacturers to schedule preventive maintenance, reducing downtime and extending equipment lifespan, which is especially beneficial for capital-intensive industries like automotive manufacturing.

Quality Control and Compliance

Consistent quality control is essential, particularly in highly regulated industries like automotive and aerospace. A study on lean manufacturing practices in automotive manufacturing shows that integrating quality control within production workflows reduces defects and maintains regulatory compliance.

BMP systems with embedded quality management functions provide real-time quality monitoring across production stages, allowing manufacturers to identify defects immediately and make adjustments as needed. This ensures that quality standards are maintained and minimizes rework, improving both product quality and customer satisfaction.

Conclusion

The deployment of BMP systems is vital for manufacturers aiming to optimize efficiency, manage supply chain complexities, and maintain high quality and regulatory standards. These platforms provide manufacturers with a cohesive, data-driven approach to address the challenges of today’s manufacturing landscape, supporting growth and resilience.

Source

Forbes Technology Council, "Unplanned Downtime Costs More Than You Think," Forbes.

European Commission, The Future of European Competitiveness: In-depth Analysis and Recommendations, European Commission.

Deloitte Insights, "The Supply Chain of the Future: Post-Pandemic Strategies," Deloitte.

ResearchGate, "Lean Manufacturing Practices Assessment: Case Study of an Automotive Company," ResearchGate.